Windings on motor rotor were damaged, I think the chaffing on the insulation led to a breakthrough and subsequent failure.

I had to completely unwind the rotor and rewind it with the same diameter enameled wire (the damage was on one of the innermost windings). Here we have a 220V mains, so the motor might be slightly different from the more common 110V US units.

Blender is pretty old, Vitamix wants a serious chunk of $$$ for a replacement motor. Admittedly I had to spend quite a bit of my free time to get this fixed, but it really only cost me $40 in raw materials.

Breakdown of the vitamix blender. Should've taken more photos.

What a new motor will look like, inside is essentially an open frame universal motor.

The rotor out of the motor and me unwinding motor. I had to remove the center insulation pieces all around and document how each winding was interconnected.

Another shot of the old windings.

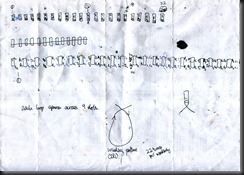

I drew a little diagram to sort out what goes where. The motor had 22 commutator segments and the same number of slots for the wires to wind around. Each winding was 22 turns of enameled wire.

The motor partially wound, I elected to solder every end onto the commutator for a more reliable electrical connection.

Cleaning the completed motor to prepare for application of red enamel.

Red enamel applied on one side.

The original bearings on the rotor were made by NMB, 608SS. SKF does the 608RS that's also a rubber sealed bearing.

After the enamel has cured, this is what the rotor looks like.

Replacement bearings side by side with the existing ones.

I had to grind and cut off parts of the bearing to remove it piece by piece to get them in. There was insufficient clearance to pull them off.

Bearing inner race still left on shaft, for this challenging location I ground 2 flats on the inner race and used a vice to apply pressure until the inner race cracked and separated from the shaft. Usually this works quite well because the races are super hard.

Replacement bearing now on.

Motor assembled together, sans the 2 brushes.

Motor assembled into the blender.

The ass end of the motor/blender. A plastic impeller that moves air for cooling the motor goes here.

The blender finally together. It was tested out and it really kills ice cubes (we tried blending a bunch of ice).

On a side note. Happy new year everybody 2015 went by really fast for me, here’s to 2016.

Update: 17th April 2016

The Mechanic has kindly went ahead and did up a professional looking diagram of how the motor is wound up. I hope the motors he has get fixed.

Note that the commutator is not shown in the top down view, only the windings are.

![20151230_150104_Richtone(HDR)_thumb[1] 20151230_150104_Richtone(HDR)_thumb[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgxybQT24f6WP6ZsxVsLO0O78pJs3DQ6KKZIL8g2diM3wa1Xfv5vAnETuU4LXa8Wgj7QtxjgfeUOjFvIBSV-EcVGwJYJxk1L0FKlXKdhrU1eV6X-EJCCFtX59f0OQZrtMJCaSkyhSLsiwQ/?imgmax=800)

can U show a diagram of how the the on/off-hi/lo switches were wired ? thank you

ReplyDeleteI don't have the blender with me now, but if you take a picture or draw a diagram of what you have now I think we'll be able to figure that out.

DeleteI only pulled the required wires away to get the motor out. So that means disconnecting the 2 brushes as well as some of the overheat protection circuitry.

Hi I am trying to unwind my vitamix motor. Do you have a higher resolution image of your diagram? It might help me complete mine. Thank you! Any tips on winding?

ReplyDeleteI have updated the post with the original scan of my crappy drawing. Basically I just marked one section of the commutator (and that's what I defined as the 1st commutator). I can't remember exactly which slot on the armature I marked as 1st, because it's been awhile, it should be the 1st slot to the right directly under the commutator I marked as 1.

DeleteI don't know if the diagram is of any help to you, it will probably help if you have some remaining windings left over that you haven't removed to take reference from, your motor might actually be completely different from mine.

Wind the coils as tight as you possibly can, especially at the start, as it approaches the end, it gets increasingly difficult to keep it all within the space provided because they will all overlap at the top and bottom of the armature.

Thank you so much for the diagram. I have taken the liberty and created a full blown diagram and would like to send it to you to make sure that it is correct. I do have an original motor that I have yet to unwind but was waiting to understand a bit more before taking it apart. I would like to be able to send my diagram to you. please let me know where I can send it. thanks!

DeleteYou can send it to me via Email at fox3.aim120ATgmail.com

DeleteI'll look it through and see if it's anything similar to mine.

Ok, sent. If you dont see it in your inbox, look in your spam.

DeleteWhere can I buy the commutators?

ReplyDeletefantastic stuff dude just the info I needed to fix my blender

ReplyDeleteCan you share what gauge winding wire you used and or LINK to where you purchased it?

ReplyDeleteI have "The Quiet One" and want to make sure that I purchase the correct winding before i begin this repair.

I measured mine and bought a roll from RS Components, mine ended up being 0.4mm, which might be different for yours.

DeleteMouser, Digikey, Farnell, RS Components should have the right wire, look for the correct diameter and the highest temperature rating you think you're gonna need :)

Where can i buy a rotor. The rotor on my Vitamix vm0115e is a bit curved. I am interested in buying only the rotor, as the motor is at a fine state.

ReplyDeleteI hope i am not too late for the party.

Also, any site of which i can buy and order replacement components, are more than welcome.

Thanks a lot!

I've never seen the rotor listed as an available part anywhere. You'd have to get a full replacement motor.

DeleteNot sure where you are located, but I see motors listed on Amazon as well as replacement part dealers. Failing that I also frequently see them listed on Ebay.

Pls how can I rewind the vitamix blender armature with 22 slots

ReplyDeleteI've put all the data here for a rewind.

Delete