Windings on motor rotor were damaged, I think the chaffing on the insulation led to a breakthrough and subsequent failure.

I had to completely unwind the rotor and rewind it with the same diameter enameled wire (the damage was on one of the innermost windings). Here we have a 220V mains, so the motor might be slightly different from the more common 110V US units.

Blender is pretty old, Vitamix wants a serious chunk of $$$ for a replacement motor. Admittedly I had to spend quite a bit of my free time to get this fixed, but it really only cost me $40 in raw materials.

Breakdown of the vitamix blender. Should've taken more photos.

What a new motor will look like, inside is essentially an open frame universal motor.

The rotor out of the motor and me unwinding motor. I had to remove the center insulation pieces all around and document how each winding was interconnected.

Another shot of the old windings.

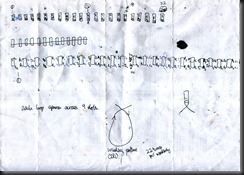

I drew a little diagram to sort out what goes where. The motor had 22 commutator segments and the same number of slots for the wires to wind around. Each winding was 22 turns of enameled wire.

The motor partially wound, I elected to solder every end onto the commutator for a more reliable electrical connection.

Cleaning the completed motor to prepare for application of red enamel.

Red enamel applied on one side.

The original bearings on the rotor were made by NMB, 608SS. SKF does the 608RS that's also a rubber sealed bearing.

After the enamel has cured, this is what the rotor looks like.

Replacement bearings side by side with the existing ones.

![20151230_150104_Richtone(HDR)_thumb[1] 20151230_150104_Richtone(HDR)_thumb[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgxybQT24f6WP6ZsxVsLO0O78pJs3DQ6KKZIL8g2diM3wa1Xfv5vAnETuU4LXa8Wgj7QtxjgfeUOjFvIBSV-EcVGwJYJxk1L0FKlXKdhrU1eV6X-EJCCFtX59f0OQZrtMJCaSkyhSLsiwQ/?imgmax=800)

I had to grind and cut off parts of the bearing to remove it piece by piece to get them in. There was insufficient clearance to pull them off.

Bearing inner race still left on shaft, for this challenging location I ground 2 flats on the inner race and used a vice to apply pressure until the inner race cracked and separated from the shaft. Usually this works quite well because the races are super hard.

Replacement bearing now on.

Motor assembled together, sans the 2 brushes.

Motor assembled into the blender.

The ass end of the motor/blender. A plastic impeller that moves air for cooling the motor goes here.

The blender finally together. It was tested out and it really kills ice cubes (we tried blending a bunch of ice).

On a side note. Happy new year everybody ![wlEmoticon-smile[2] wlEmoticon-smile[2]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgc-USC3SnmwrGlQ_ZrXiPl2Lje6KMgwsKBK7vKUK6V4gKYO6wiD-t-Ll2ONDvepPANHKG33j73Glj7KZw1fJIcVh6qJtTAgX9U_hPniTpVMbQeuFCUUsYmQfTU2q6OvsawuIe7MKgAJBU/?imgmax=800) 2015 went by really fast for me, here’s to 2016.

2015 went by really fast for me, here’s to 2016.

Update: 17th April 2016

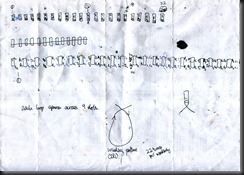

The Mechanic has kindly went ahead and did up a professional looking diagram of how the motor is wound up. I hope the motors he has get fixed.

Note that the commutator is not shown in the top down view, only the windings are.

![20151230_150104_Richtone(HDR)_thumb[1] 20151230_150104_Richtone(HDR)_thumb[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgxybQT24f6WP6ZsxVsLO0O78pJs3DQ6KKZIL8g2diM3wa1Xfv5vAnETuU4LXa8Wgj7QtxjgfeUOjFvIBSV-EcVGwJYJxk1L0FKlXKdhrU1eV6X-EJCCFtX59f0OQZrtMJCaSkyhSLsiwQ/?imgmax=800)