B0rked E51 keypad, some keys weren’t functioning (right function key, 1, 2,3 and *). Decided to try and fix it.

Still got the box… LOL. To disassemble the phone, pull the battery and sim, then undo the 4 torx screws on the back.

This will release the front panel. Resulting in the below

Then undo the top 2 torx screws on this side, and then pull the metal shield downwards (there are 2 metal tabs hanging over the board that hold it in), and then carefully flip the shield over, exposing the keypad connector.

Using a non-conductive (preferably non sharp as well to avoid scratching the PCB accidentally) tool, free the keypad connector, becareful to not let the phone flop around as the LCD is now free to move, those darn flex circuits are bloody easy to tear in 1/2.

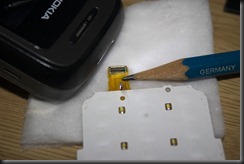

Upon closer inspection. I found the problem. It’s some kinda corrosion that went through the covering Pyralux or Kapton coating into the copper traces below, should be due to lame manufacturing. Here’s my try at cheap-ass macro photography (flipped a lens around).

Can’t see it very well, but it’s a break. The dark thing on top is actually the tip of a pencil, that’s how small this trace is.

Next I carefully (using a sharp scapel) scrapped the coating above the trace off, exposing the raw copper below.

The break is now a lot clearer, measuring with a DMM (digital multi meter) confirmed there was no continuity. I then patched it with some fine wire and a little solder.

The trick to soldering onto flex circuits is to not to heat it for too long and use minimal heat (25W soldering pencil is my weapon of choice), you can’t tin the trace all that well also, the coating around seems to break down before the solder melts, covering the trace with a gooey mess that prevents the trace from taking solder properly.

What I did was lightly flux the trace, tin the piece of wire, form a L shape with the wire, lay it exactly on top of the trace I wanted to patch, and then apply heat and hope for the best. After that, inspect the joint and lightly tug on the wire to make sure it’s firm, then trim the remaining wire off. It’s butt ugly, but it works.

Next I put the phone back together again (humpty dumpty would be proud) and all the keys now freaking work. xD

nice work. I was just about to do the same and did a quick google check, found you post and was happy to go ahead. I was lucky a solder spot fixed mine.

ReplyDelete